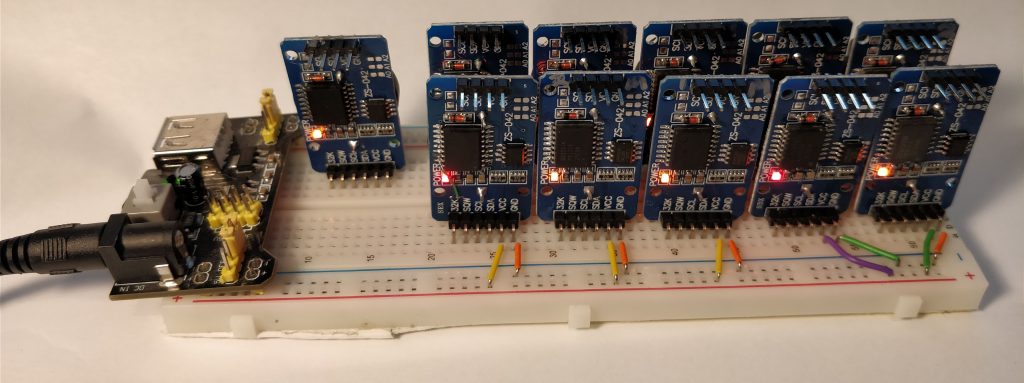

It’s been just under 5 months since I simultaneously synchronized ten DS3231/DS3231M RTCs as part of a long-term experiment to measure their drift. Of the ten, seven are crystal-based DS3231 chips, while three are DS3231M chips. Since they’re all on the same breadboard connected to the same power supply, all of them have been subject to the same physical conditions of temperature, movement, voltage, etc. insofar as I can control for them in my apartment.

In the table below “Number” is the identifying number of each chip I arbitrarially asigned to uniquely identify each one, “Type” refers to its type (all the DS3231 modules are marked as the wide-temperature-range SN type, while the DS3231Ms are listed as M. The official DS3231M chip (#2) I received directly from Maxim is marked with an asterix.), “Offset” is the aging offset in register 0x10 expressed in decimal form, “PPM” is the stability in parts per million, and “Drift” is the number of seconds the clock has drifted since the start. For both the PPM and Drift columns, a positive value indicates that the RTC has run faster than the NTP-synchronized system clock while a negative value indicates the RTC has run slower than the system clock.

All results were collected over a 26 minute period starting 12904549 seconds after the clocks were first synchronized. Each clock was measured three times and the resulting values averaged and rounded to two decimal places. Keep in mind that this dataset consists of just two data points (zero drift at the start, and the measured drift now) for each clock: unlike Dan, who continuously collected data and made many nice graphs, I set the clocks and essentially ignored them for five months.

Anyway, I digress. Here’s the results:

Number Type Offset PPM Drift 0 SN -6 0.19 2.46 1 SN 0 -0.69 -8.96 2 M* 0 -1.62 -20.85 3 M 0 -3.06 -39.54 4 M 0 -2.76 -35.65 5 SN 0 0.16 2.07 6 SN 0 0.01 0.10 7 SN -15 0.33 4.32 8 SN 0 0.08 0.98 9 SN 0 -0.05 -0.60

Some commentary, bullet-pointed for your reading pleasure:

- All clocks are within their advertised tolerances (2 ppm for the crystal-based clocks and 5 ppm for the MEMS-based clocks).

- Five of the seven crystal-based DS3231 chips run fast, while two run slow. All three of the MEMS-based DS3231M chips run slow.

- Clock #6 has essentially no drift whatsoever. There’s nothing particularly noteworthy about it: just luck of the draw.

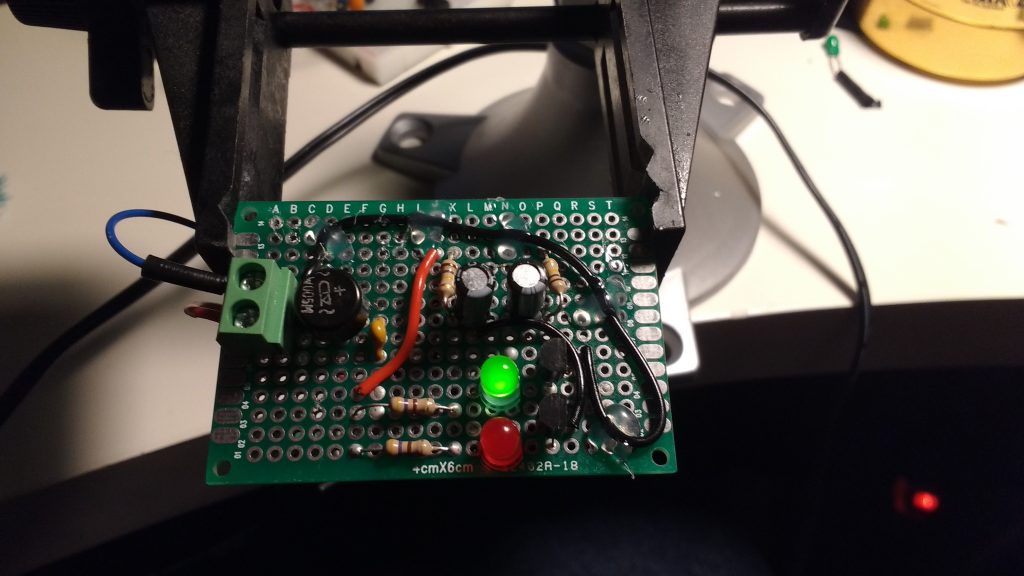

- The Raspberry Pi used to set the clocks in September was also used to measure the offset today. It has run continuously since the clocks were set, and has been synchronized continuously to another Raspberry Pi (+/- 0.1 ms), which was in turn synchronized to GPS using a Motorola Oncore UT+ receiver (+/- 150 ns). Time errors on the Pis are negligible.

- I have two PCA9548A I2C switches that allow me to wire up all the clock chips and switch between them using software commands rather than needing to physically move wires around. This makes life easy.

- At the start of the measurement, I had observed each of the clocks’ outputs using my oscilloscope and compared them to a GPS-synchronized PPS signal. Clocks #0 and #7 drifted faster than the others but were still within the advertised specs (unfortunately I didn’t write down how fast they were drifting and have since forgotten). I adjusted the aging register until the short-term drift was minimal; the results are acceptable, though I note they drifted the most of any of the crystal-based clocks.

- All ten clocks are part of a cheap module available on eBay from various Chinese sellers. The module comes with either a DS3231 or DS3231M chip (the sellers don’t sort them so you can get either type at random) of various vintages. The oldest I’ve seen is from 2006. None of the chips seem to be new, with various smudges and wear visible on the face of the chip, so they’re likely pulled from old equipment and reused on these boards. Even so, they work well.

- Each board also comes with a 24C32A I2C EEPROM, which is nice, but not strictly necessary. I use them for storing the aging offset in case I remove the backup battery and want to tune it again without using the oscilloscope.

- The boards also come with a holder for a backup coin cell battery. Critically, the boards are also wired with a 2N4148 diode and a 200-ohm series resistor feeding the positive terminal of the battery, presumably for use with a (not included) LIR2032 rechargeable coin cell. If you use a non-rechargeable CR2032 coin cell you must remove either the diode or resistor or else the circuit will try to charge the coin cell battery, which can damage the battery. I’ve removed the battery holder entirely from one or two other test boards and the charging circuit works well to charge a backup supercapacitor, but the charging circuit must be removed or disabled if you use non-rechargeable coin cell batteries.

- The data here is just a brief summary; I have more detailed data in a spreadsheet that’s available upon request.